Do you know the secret to unlocking your car’s true performance and efficiency potential? The answer lies in properly adjusting your engine valves. This often-overlooked maintenance task can have a profound impact on your vehicle’s power, fuel economy, and even emissions. But where do you begin?

In this comprehensive guide, we’ll walk you through the step-by-step process of adjusting your car’s engine valves. We’ll cover everything from understanding the underlying science to troubleshooting common valve-related issues. Whether you drive a pushrod or overhead camshaft engine, you’ll learn the essential techniques to keep your valvetrain in top shape. So, let’s dive in and unlock the true potential of your vehicle!

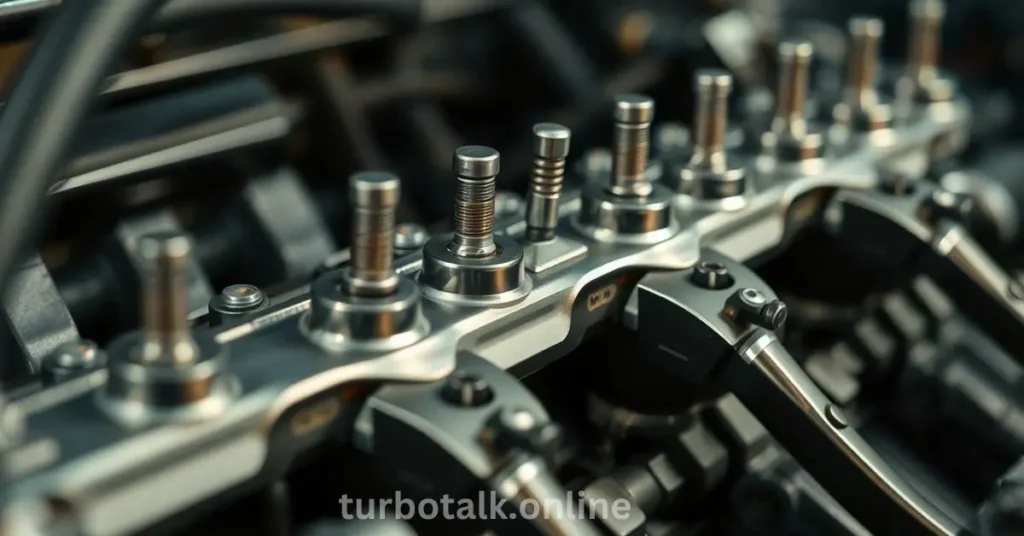

Understanding Valve Adjustment Basics

Adjusting your car’s engine valves is key for top performance and efficiency. These valves manage air and fuel flow into and out of the cylinders. They must match the valve clearance specifications for your vehicle.

Importance of Proper Valve Adjustment

Keeping the right valve clearance is vital for your engine’s health and life. Mechanics say Honda valve clearances get tighter over time, hurting fuel economy if not fixed. Adjusting the exhaust valves can boost low-end power and torque but might reduce high-end horsepower.

Regular valve adjustment is a must for engine service and tune-up procedures. Skipping this can lead to more oil consumption, rough idling, and serious valve train component failures.

Learning about valve adjustment helps your car’s engine run its best. Whether you’re doing a DIY car repair or getting help from a pro automotive valve service.

Preparing for Valve Adjustment

Before you start adjusting your car’s engine valves, make sure you have the right tools. It’s also important to consider the temperature. Getting ready for this task will make it easier and more effective, keeping your engine running smoothly.

Tools and Supplies Needed

You’ll need a feeler gauge and a torque wrench to adjust your car’s engine valves. These tools help you measure and set the valve clearance as the manufacturer suggests. Some engines might need special tools to adjust the shims in shim-over-bucket valvetrains.

Temperature Considerations

The engine’s temperature affects the valve clearance. Metals expand with heat, so you need to follow the manufacturer’s temperature guidelines. An infrared temperature gun is a quick way to check the engine’s temperature.

Proper preparation and attention to detail are key when adjusting your car’s engine valves. By gathering the right tools and understanding temperature needs, you’ll get the best results and keep your engine healthy.

Adjust Car Engine Valves

Adjusting your car’s engine valves is key for top performance and fuel use. It’s the same for both overhead camshaft (OHC) and pushrod-operated overhead valve (OHV) engines. Let’s explore how to adjust these valves.

First, turn the engine to the right camshaft position. Make sure each intake or exhaust follower is close but not touching the cam’s heel. This makes it easier to adjust all valves at once. Use a feeler gauge to check the valve lash or clearance against the specs.

- Loosen the tappet locknut to adjust the valve clearance.

- Put the feeler gauge between the valve stem and the rocker arm or pushrod. Adjust the valve until the gauge slides through with a bit of resistance.

- Tighten the tappet locknut while holding the adjustment screw. Be careful not to change the clearance.

- Do this for each intake and exhaust valve. Follow a specific order to make sure all valves are adjusted right.

Always use a torque wrench to tighten parts as recommended. This keeps the valve train components strong. By following these steps, you’ll keep your engine’s valves in the right clearance. This boosts performance and fuel efficiency.

Remember, valve clearance specs vary by vehicle. Always check your owner’s manual or a repair guide for the right info. Regular valve adjustments are vital for your car’s engine health and longevity.

Working with Shim-Over-Bucket Valvetrains

Adjusting valve clearances in a shim-over-bucket valvetrain needs extra care. These systems use shims between the valve stem and the rocker or follower bucket. It’s key to measure and replace these shims right to keep the engine running well.

Measuring and Replacing Shims

To adjust valves, you’ll need a feeler gauge to check the clearance. Take note of these measurements to pick the right shim thickness. Sometimes, you might need to remove the camshaft to get to the shims.

Special Tools and Precautions

Adjusting a shim-over-bucket valvetrain needs special tools like a shim removal tool or a valve spring compressor. These tools help you work on the shims safely. Also, some designs have an interference fit, so be careful not to damage the valves.

By following the right steps and using the right tools, you can keep your engine running smoothly. This ensures it lasts longer and performs better.

Verifying Valve Timing

After adjusting your car’s valves, it’s key to check the valve timing. Engine timing needs to be just right, or it can hurt your car’s performance. Our techs often find timing issues when they remove the valve cover for service.

Getting the valve timing right is vital for your engine’s best performance. Here are some tips to check if your engine’s timing is correct:

- Look at the timing belt or chain. It’s wise to replace timing belts every 50,000 miles to avoid failure. If your car has a timing chain, you might need to take it apart to inspect it well.

- Check the timing marks on the crankshaft and camshaft pulleys or gears. They should line up as the factory says. A slipped timing mark on the harmonic balancer can trick you, so also check the piston position.

- Watch how the valves or lifters move to see if the timing is right. You can do this without taking apart the engine in many cases.

Changing the valves doesn’t mess with the engine’s timing. It’s a different task that needs careful attention. By carefully checking and confirming your valve timing, you can make sure your engine is running smoothly. This will improve your car’s performance and efficiency.

Replacing Gaskets and Seals

Keeping your car’s engine in top shape means replacing valve cover gaskets, spark plug tube seals, and fastener grommets. While some valve cover gaskets can be reused, most need to be replaced during valve adjustments. This step is key to a tight seal and avoiding expensive leaks later on.

Using neoprene gaskets and the right sealants is what manufacturers suggest for the best results. Be careful not to over-tighten valve covers as it can cause leaks. It’s important to follow the correct torque sequences and sealant applications. Even with neoprene gaskets, uneven clamping can lead to leaks. That’s why a small amount of sealant is often needed, especially at gasket corners or where covers meet bearing caps or end-plugs.

Importance of Fresh Gaskets

It’s vital to replace engine gaskets, like cylinder head gaskets, during scheduled engine service or overhaul. This is part of good preventive maintenance and keeps your vehicle running well for longer. New gaskets and seals keep the cylinder head assembly and cylinder head servicing in top condition, preventing leaks and improving engine performance.

Proper Torque Sequences and Sealants

When putting back valve covers or other parts, always follow the manufacturer’s torque sequences and use the right sealants. This ensures a tight and leak-free fit, protecting your engine from damage. Skipping these steps can result in expensive repairs later on.

Troubleshooting Valve-Related Issues

Many car makers suggest adjusting valves every 15,000 to 45,000 miles. But, these times are often ignored. Your vehicle’s valve clearance may actually tighten over time, causing poor fuel economy. Checking your engine’s manifold vacuum regularly can help spot when valve adjustment is needed.

Low or erratic vacuum readings might mean your valves need a closer look. Valve noise and engine misfiring are also signs of valve trouble. For some cars, like Mercedes, tight valves can cause a whole cylinder to misfire.

Carbon Buildup and Other Valve Problems

Another issue is carbon buildup on the valves, which can lead to high NOX emissions and misfiring, especially in Jeep 4.0L engines. In these cases, more extensive valve-based repairs, like replacing valves or decarbonizing the engine, might be needed.

- Valve stem seals and valve guides can wear out, causing valve problems.

- Regular vacuum testing and fixing any signs of needed valve adjustment can prevent bigger valve issues.

By watching for signs of valve-related issues, you can fix problems early. This keeps your engine running well and efficiently.

Conclusion

Adjusting your car’s engine valves is a key maintenance task. It ensures your engine runs well and lasts longer. Knowing how to adjust valves properly is crucial for your car’s performance.

Whether your car has a traditional pushrod valve train or an overhead camshaft, adjusting valves is essential. Regular checks and adjustments can prevent problems like noise and reduced performance. It also avoids costly engine failures.

Setting your engine’s valve clearances right is a smart investment. It keeps your car running smoothly and efficiently. It also helps your engine’s parts last longer. So, don’t shy away from adjusting your valves. Your engine will appreciate it.

Read More